CAFS Explained

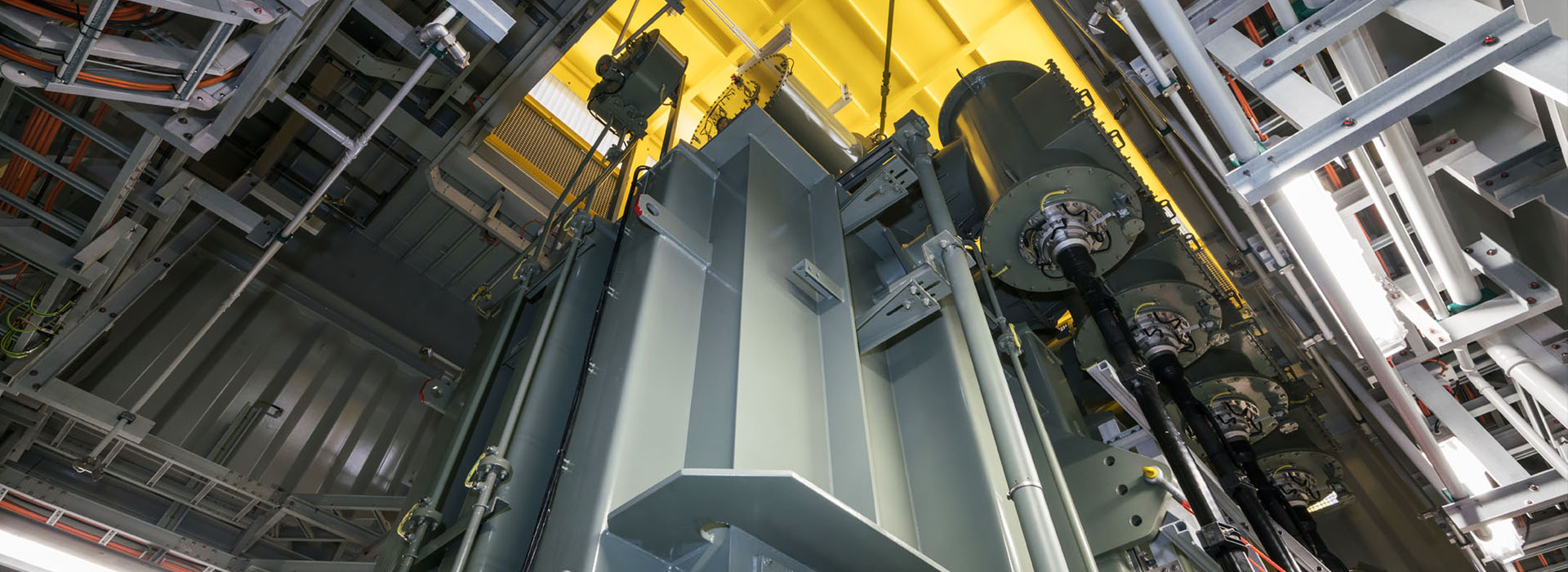

ICAF System Description & Design

The ICAF SYSTEM is a deluge-type system that uses a balanced piping network and can be activated by electric, pneumatic or manual release. The system can be configured with multiple mixing chambers and can have multiple zones. Each system is designed and installed as per the current NFPA 11 standard. FIREFLEX® provides design assistance with respect to piping and nozzle layout, including hydro-pneumatic calculations, and offers system start-up service including onsite discharge testing and commissioning.

The system water supply can be provided by a water pressure vessel or can be connected to a city fire main or fire pump system. The air supply is provided by high-pressure air cylinders that are factory assembled onto cylinder banks and include a high-pressure manifold and pressure regulator(s).

The foam concentrate is stored in a stainless steel pressure vessel. The foam concentrate tank and water supply tank, if applicable, are pressurized with compressed air upon system actuation.

Water, compressed air and foam concentrate are then injected into the mixing chamber(s) mounted in the cabinet. CAF is generated in the mixing chamber and then flows through the system’s piping network

towards the distribution nozzles.

CAF is discharged in or on the hazard using special discharge devices which effectively distribute the foam evenly over the nozzle’s area of coverage. In addition to coverage, the TAR and FPO nozzles are specifically designed to maintain CAF quality preventing degradation of the CAF generated in the mixing chamber.

ICAF SYSTEMS are factory assembled, tested in cabinets and include all hydraulic, pneumatic and electrical devices required for proper operation.

The Integrated Compressed Air Foam system offers many benefits and advantages

Significant

Reduction in Foam and

Water Required

ICAF uses four times less water and up to six times less foam concentrate compared to foam-water systems.

ICAF

FM Approved Discharge Devices

CAF is discharged in or on the hazard using special discharge devices which effectively distribute the foam evenly over the nozzle’s area of coverage. In addition to coverage, the TAR and FPO nozzles are specifically designed to maintain CAF quality preventing degradation of the CAF generated in the mixing chamber.

Ceiling Nozzle Configuration

The TAR-225C is an open-type ceiling nozzle used for area protection of flammable or combustible liquids spill or pool fire hazards and is specifically designed to effectively distribute CAF over a remote area.

Located at the ceiling level the ICAF Nozzle is designed to discharge CAF in a 360° radius over a maximum area of 150 ft2 (13.9 m2) when used on hydrocarbon liquids and 100 ft2 (9.29 m2) when used on polar solvents.

Specific Hazard Configuration

The TAR-225L is an open-type directional nozzle which is specifically designed to discharge CAF over exposed horizontal or vertical surfaces of specific equipment, and is effective on cascading fires.

The TAR 225L nozzle spacing shall be based on the spray pattern design principle. Nozzles shall be spaced and aimed so that their spray patterns will cover all surfaces adequately.

Foam-Powered Oscillator

The FPO is an open-type oscillating nozzle that is specifically designed to project CAF horizontally over a wide area. It is an effective discharge device for low-level protection. The CAF can be delivered via a 90° or 180° arc of oscillation with discharge range up to 92 ft. The FPO nozzle is self-propelled by the CAF discharge and does not require any electrical or hydraulic connection, considerably simplifying installation.

Reduced

Infrastructural Requirements for Fire Protection

Water Supply

ICAF can eliminate or reduce the size of water supply tanks & fire pumps

Drainage and Containment

ICAF can eliminate or reduce the size of drainage and containment systems including spill tanks and oil separators

Disposal Costs

The significant reduction in foam and water required for ICAF reduces the costs associated to clean-up and disposal of foam during discharge testing or after a fire.

Enchanced

System Performance

Full-scale fire tests have demonstrated that ICAF is a very effective extinguishing mechanism for class B fires. The unique physical properties of ICAF foam with a 10:1 expansion ratio combined with long drain times provide improved extinguishing and burnback performance. Furthermore, its ability to stick to vertical surfaces enabled the ICAF to be Listed for cascading fires. System performance can be a deciding factor in critical applications where it is desirable that system performance exceeds the minimum requirements set out in published codes or standards.

Improved

Visibilty in the hazard

In comparison to water-based systems, CAF’s unique physical properties significantly reduce steam production and thereby improve visibility during and after a fire. The CAF blankets the fuel surface and therefore does not cause visual impairment often associated to high-expansion, total flooding foam systems.